Water Treatment

Water Treatment is in Pulsafeeder’s DNA

For more than 70 years, Pulsafeeder pumps have been used to treat water at hundreds of industrial & municipal plants around the globe.

Municipal Water Treatment Applications include (but are not limited to):

- Metering of sodium and calcium hypochlorites for disinfection

- Acid and caustic injection for pH control

- Injection of potassium permanganate for manganese and iron removal

- Metering of alum or sodium aluminate as a coagulant aid

- Metering of polymers for primary coagulation

- Injection of filter aid slurries

- Metering of lime slurries in softening and pH control

- Ammonium sulphate or aqua ammonia in production of chloramines

- Metering activated carbon slurries for taste and odor control

- Injection of fluoride compounds

Applications

Cooling Tower Water Treatment

Boiler Water Treatment

Industrial Wastewater Treatment Applications

- Metering of sodium hypochlorite and hydrogen peroxide for disinfection

- Metering acids and caustics for pH control

- Sodium bisulfite metering for de-cholorination

- Metering of alum or sodium aluminate as a coagulant aid

- Anionic and cationic polymer injection for phosphate removal, coagulation and filtration

- Caustic soda (sodium hydroxide) metering for metal removal, pH control, and cyanide removal

- Acid and caustic injection for regeneration of resins

- Injection of potassium permanganate for manganese and iron removal

- Metering of Bromine for disinfection (for cooling towers)

- Injection of copper sulfate for algae control in cooling tower water

- Metering of polymers for primary coagulation

- Ferric chloride and alum injection for coagulation

- Copper sulfate injection for algae control

- Methanol injection for denitrification

- Metering of lime slurries for pH control, corrosion control and coagulation

- Metering activated carbon or diatomaceous earth slurries for odor and color control

Metering pumps used to deliver chemicals should be selected by criteria specific to the process, such as:

- Flow Rates & Pressure – as required by the process

- Corrosion resistance – to the chemical being pumped

- Accuracy – to deliver precisely the amount of chemical needed for a process

- Reliability – to ensure sustained and predictable operation

- Simplified maintenance – to minimize costs and maximize plant uptime

- Safety – to protect plant employees, and the surrounding environment

Common Products for this Application

PULSAtron

Typical applications are acids, caustics, polymers, bleaches, pH control, solvents, dyes/ink, catalyst, cleaning agents, and much more.

PulsaPro

PulsaPro Series is a perfect fit for Water & Wastewater Treatment, Oil & Gas and Industrial applications.

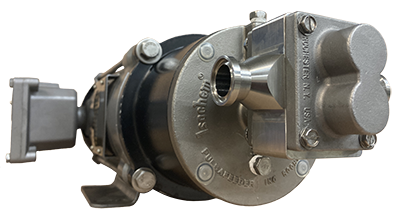

IsoChem

ISOChem magnetically driven sealless gear pumps offer the reliability you need to safely handle clear lubricating and non-lubricating liquids. A wide variety of material options provide versatility for pumping low or high viscosity fluids over a broad range of temperatures and pressures.

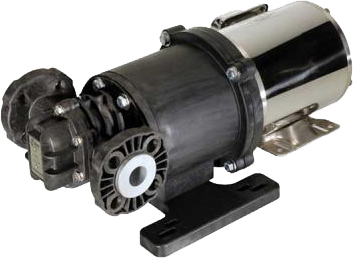

Eclipse

Eclipse rotary pumps are an ideal fit for many corrosive liquids. From acids to bases, we cover the entire pH scale.

MicroVision EX

The MicroVision EX is a microprocessor controller used in cooling tower applications.

MicroVision Boiler

The MicroVision Boiler Controller is configured specifically for boiler water control featuring a reliable temperature compensated conductivity probe.

MicroVision

MicroVision is designed for cooling tower and boiler applications.

MicroVision Condensate

The MicroVision Condensate Controller delivers condensate return monitoring with a reliable and accurate temperature compensated conductivity probe.

MicroVision Timer

The MicroVision Timer is a microprocessor-based selectable timer controller, designed specifically for timer based control applications.

MicroTrac

The MicroTrac is a microprocessor based feed and bleed toroidal conductivity controller designed to control conductivity and feed inhibitor in cooling tower systems.