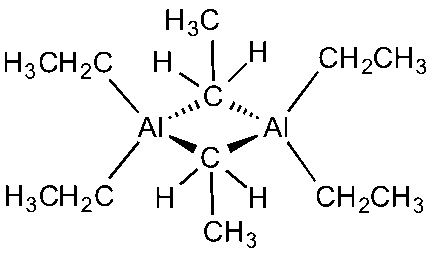

Triethylaluminum / TEAL

What is TEAL?

Triethylaluminum is a commonly used cocatalyst in the Ziegler-Natta polymerization of olefins/alkenes. This is a key chemical for manufacturing of:

- Polypropylene (PE)

- High density polyethylene (HDPE)

- Low density polyethylene (LDPE)

- Linear low density polyethylene (LLDPE)

The accurate dosing of TEAL is important to achieve the proper recipe for manufacturing as well as keeping costs in control. Safety is paramount as this material has a low flashpoint and combusts with the introduction of water.

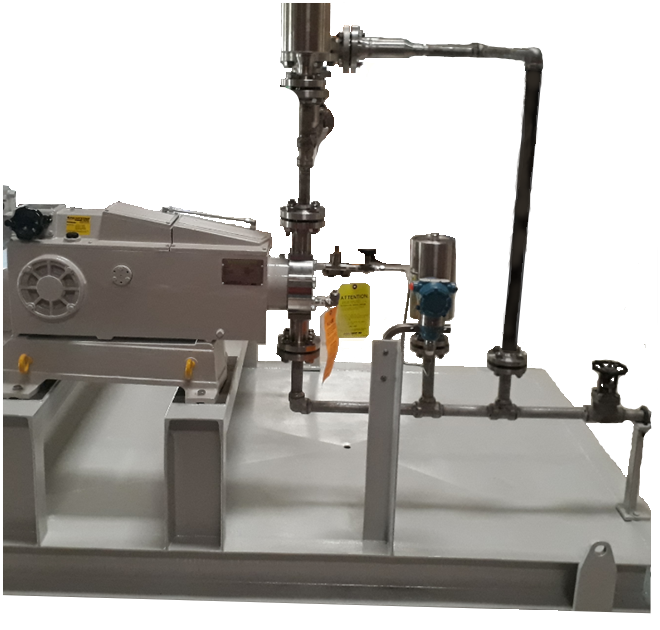

Choosing the right design, and a supplier with knowledge of handling and metering TEAL, is critical to keep your operation safely running.

Safety and Experience

Pulsafeeder has the experience to ensure that both safety and accuracy can be guaranteed when it comes to metering Triethylaluminum.

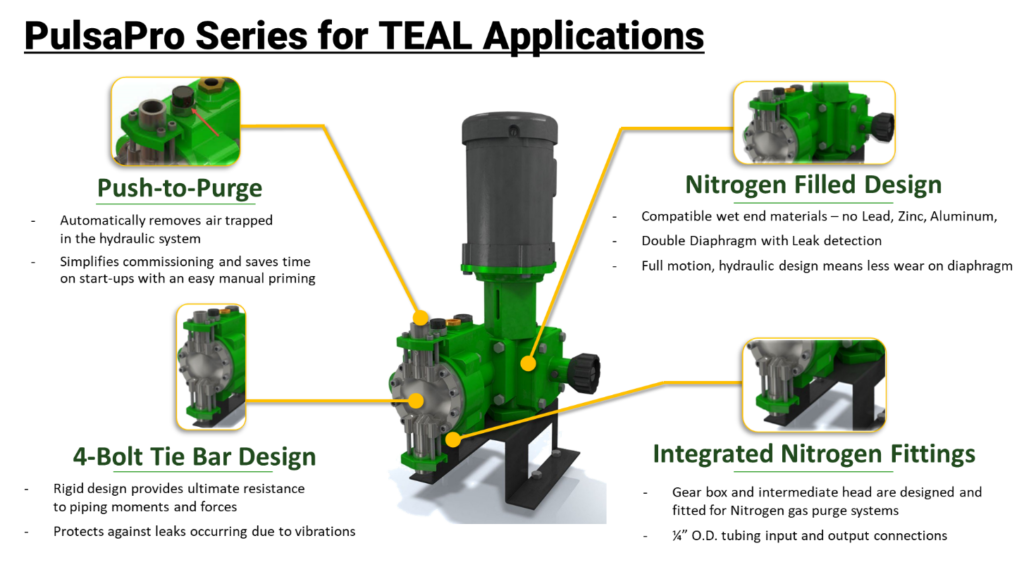

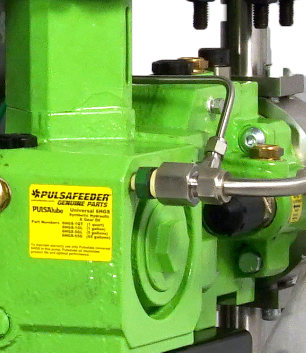

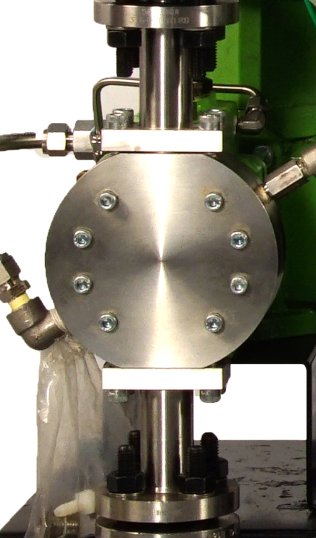

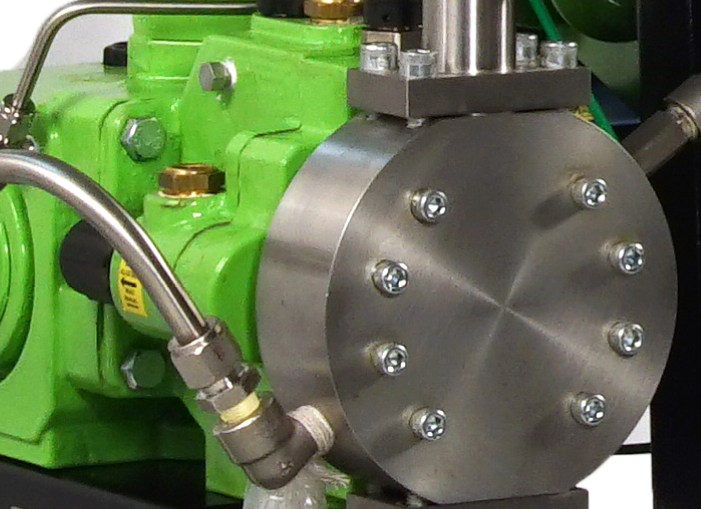

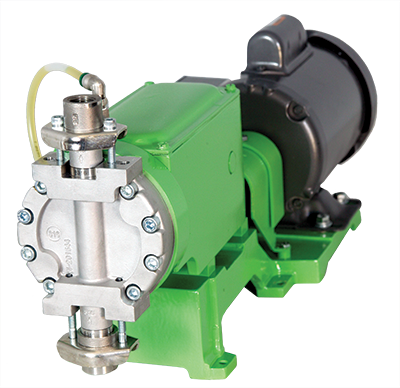

The PulsaPro Series of pumps are engineered with a double diaphragm design with integrated leak detection, nitrogen purge systems and robust construction materials to eliminate the possibility of leaks.

We design pumps with the highest quality standards, maximizing uptime and reliability for decades to come.

Designed for TEAL

- Special reagent head and check valve designs to ensure 100% leak free assembly

- Monoblock design to eliminate joints/ possible leak paths

- Double diaphragm design with hydraulic actuation and leak detection

- Nitrogen blanketing prevents pyrophoric liquid from exposure to air in the event of a rupture

- When maintenance is required, integrated nitrogen fittings allow for nitrogen to be flushed into diaphragms to remove traces of pyrophoric liquid trapped between two diaphragms

- 7120 Series Pump: Flow – 24 LPH, Pressure – 32kg/cm2g

- 7660 Series Pump: Flow – 180 LPH, Pressure – 32kg/cm2g

Common Products for this Application

PulsaPro

PulsaPro Series is a perfect fit for Water & Wastewater Treatment, Oil & Gas and Industrial applications.

Pulsa Series

From thin fluids to lime slurries, materials of construction for contact with the most hazardous chemicals and features and options to provide safe, remote and accurate dosing, count on Pulsa Series for the most demanding applications.

Want to talk Petrochemical?

Pulsafeeder works extensively with world’s largest EPC and Petrochemical Companies in Upstream/Midstream/Downstream segments. We understand the process, and the requirements for Petrochemical Industry. We invite you to contact us, we love to talk about the products, packages and support that Pulsafeeder can provide.