Rotary Gear Pumps

Simple, Safe & Reliable Rotary Gear Pumps

VERSATILITY

Eclipse Rotary Gear Pumps are suitable for both transfer and metering applications in water treatment and chemical processing, NSF/ANSI 61 Eclipse sealless gear pumps can handle a wide range of volume flows, connection sizes, fluid viscosities and temperatures.

CHEMICAL COMPATIBILITY

Available in PVDF or 316-SS, Eclipse gear pumps ensure corrosion resistance against a wide range of chemicals, making Eclipse chemical gear pumps ideally suited to handle acids, caustics, polymers, flocculants, resins, solvents & scale inhibitors.

SAFETY

Exposure to harsh chemicals from a leaking pump can cause respiratory issues for employees. Magnetically driven sealless gear pumps offer fewer points of failure. Zero leaks prevent harsh chemicals from damaging the pump, plant personnel or other equipment.

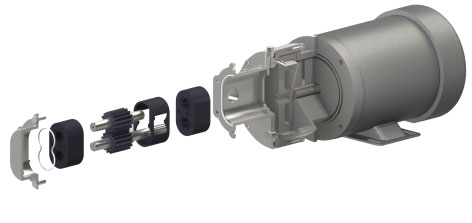

SIMPLE MAINTENANCE

With just a few moving parts, Eclipse’s rotary pumps patented front pull out design is reliable and easy to maintain. Easy access to the inner workings enables the pump to be maintained in place with a minimum number of tools – minimizing downtime and eliminating the need to move the pump to a repair shop. Pulsafeeder’s KOP (Keep-on-Pumping) kits provide all of the spare parts required to return the pump to as-new condition. For warranty information click here.

PERFORMANCE

Eclipse, Rotary Gear Pump was specifically designed to handle harsh chemicals, making it a viable alternative to other types of pumps. Eclipse offers:

- Greater efficiency, reliability and lower cost-of-ownership than centrifugal pumps operating below B.E.P

- Less maintenance and greater reliability than peristaltic pumps

- Eclipse is ideal for applications where +/- 2% metering accuracy will suffice and accuracies of 1% or better are achievable with a closed loop system, making Eclipse is an affordable alternative to diaphragm pumps.

Pulsafeeder, Inc., Eclipse pump’s compact design and pulse-free dosing results in a smaller footprint and reduced piping sizes.

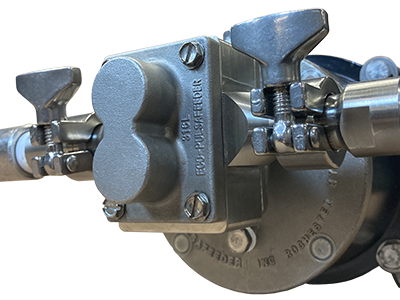

FEATURES

- Short port-to-port dimensions optimize space

- Integrally cast design eliminates the need for multi piece tri-clamp npt adapters

- Tri-clamp fittings allow for easy pump cleaning and maintenance

TRI-CLAMP SANITARY CONNECTIONS

ECO and ISOChem pumps with tri-clamp (sanitary) fittings are often required on botanical extraction equipment used to produce products such as “Essential Oils” or other plant extracts. They provide easy pump disconnect for cleaning and maintenance and the smooth flow-through ports minimize the amount of crevices and cavities where product can be trapped.