Botanical Extraction

Pumps for Botanical Extraction

Pulsafeeder has both the product portfolio and experience in botanical extraction processes to help tailor your system to your specific needs.

Our rotary gear pumps are routinely used in the following processes:

- Wiped Film Evaporation

- Thin Film Evaporation

- Solvent Recovery

- Fine Chemical Distillation

- Liquid Separation

- Plant Extraction

Botanical Extraction applications employ rotary gear pumps to transfer tincture, solvent, terpenes and crude plant oil from one process step to another. These pumps are commonly referred to as feed pumps, distillate pumps and bottoms pumps in vacuum separation processes. Within these applications, the pressure, temperature and viscosity can vary greatly at each part of the process which means that one pump does not fit-all.

Gear pumps reliably handle these fluids and our experts help extraction OEM’s to ensure they are using the best materials of construction and sealing options for each set of conditions.

Pulsafeeder’s ECO and ISOChem gear pumps, installed with expert advice from our local representatives and in-house engineers, help extraction system manufacturers to improve system uptime, reduce cost and drive out design complexity.

ISOChem and ECO rotary pumps, UL1389 Certified Models for Operator Safety.

INDUSTRY PROVEN

Pulsafeeder features two industry proven designs that can cover many steps of a botanical extraction process. The ISOChem gear pump series features a mag-drive sealless design that is ideal for services from full vacuum to high pressure and can handle a wide range of viscosities and simplify your system design. The ECO series is the ideal choice for positive pressure solvent recovery applications, and the perfect fit for many process steps. All Pulsafeeder gear pumps can be easily jacketed to keep the distillate and bottoms warm and at a low viscosity to optimize processin

MAXIMIZING UPTIME

Pulsafeeder rotary gear pumps can be configured to extend the life of critical pump components, providing greater process uptime. By matching materials of construction to each fluid type, with consideration of its viscosities and temperatures, premature failures and excessive maintenance can be avoided. ISOChem and ECO gear pumps feature self-lubricating bearing materials, hard enough to minimize bearing erosion, but smooth enough to provide the stainless shafts the right surface to keep them spinning efficiently.

VACUUM CONDITIONS

Additionally, the ISOChem series of pumps use a sealed “containment-can”, an inherent feature of its mag-drive design, which eliminates leakage and provides the maximum protection for operators and adjacent equipment.

SIMPLE IS BETTER

The sealless design of the ISOChem means that cumbersome seal flushing systems are no longer required. This allows a system designer to remove one more variable in the machine as well as saving on the cost of the flushing systems itself. The integrated tri-clamp sanitary fittings allow for quick connect and disconnects and easy cleaning without adding any additional fittings.

QUALITY

Our rotary pumps are designed with high grade materials and critical components are traceable with the availability of Certified Mill Test Reports (CMTR’s) on each pump. ECO and ISOChem pumps have a reputation for high quality manufacturing and we go the extra mile to stand behind our products to make sure you stay up and running.

BENEFITS

Industry Proven Designs

• Handle a variety of viscosities from thin solvents to thick extracts

• Applications up to 100 psig and down to -40°F

• Operate leak free and sealless, under vacuum, and up to 450°F with ISOChem Simple Design and Easy Service

• Integrated Tri-Clamp fittings allow easy pump removal and cleaning

• Short port-to-port dimensions minimizes piping

• Eliminate the need for seal flushing systems with ISOChem Maximize Life with the Right Materials

• Process thin fluids with self-lubricating bearings

• Extended life with hardened carbon bearings

• High temperature PEEK gears available

Simple Design and Easy Service

• Integrated Tri-Clamp fittings allow easy pump removal and cleaning

• Short port-to-port dimensions minimizes piping

• Eliminate the need for seal flushing systems with ISOChem

Maximize Life with the Right Materials

• Process thin fluids with self-lubricating bearings

• Extended life with hardened carbon bearings

• High temperature PEEK gears available

FEATURES

• Leak-Free Sealless Mag-Drive (ISOChem)

• Tri-Clamp Sanitary Connections

• Industry Proven Designs

• Chemically Compatible Gears, Bearings and Wear Plates

See how Pulsafeeder ECO and ISOChem pumps solved this equipment manufactures problems:

- Varying viscosities as the process fluids change in temperature through the process

- Matching pump materials for diverse fluids conditions

- Dealing with vacuum condition

- Removing complexity from the system to save on costs and increase system uptime

Pulsafeeder only works with distributors and extractors in accordance with local laws and regulations.

Common Products for this Application

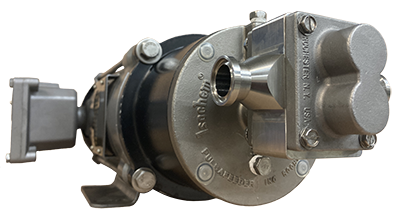

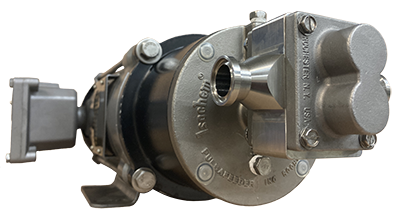

ISOChem

ISOChem Series is a compact rotary gear pump, designed to safely handle highly corrosive, hazardous, explosive, or toxic chemicals in industrial applications.

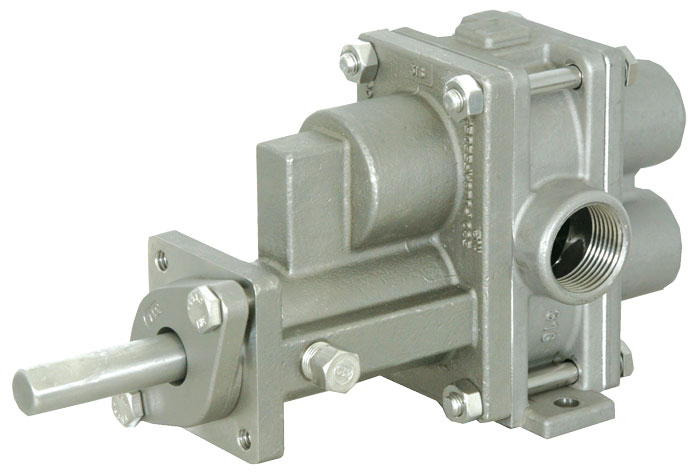

ECO Gearchem

ECO gear pumps are well suited for pilot plants, vacuum systems, and metering applications.